Even with the thickest box design and corrugated cushion, there is always the risk for damage of your items due to bumps and jars when shipping. There may also be the problem of something being fragile when you send this out. How do you keep this all safe? Well polyethylene packing foam can do the trick. This is a denser, stronger type of foam that offers better durability.

How it works

This is designed for durability and to last a bit. It is closed cell, to make it stronger, but less flexible and also breathable when compared to PU foam. Polyethylene is lightweight, shatterproof, and very hard to tear, with a good buoyancy and won’t create dust, which is good for those who need foam for their packaging. Closed cell of course, offers better absorbency of the foam and products in order to resist the waters, chemicals that can get in that’s there, and sometimes grease too.

Closed cell also implies too that this is also protected from mold, bacteria, mildew, and even rot, so you don’t have to fret about it being contaminated. PE foam is oftentimes stronger for shock absorbency and offers a better ability to dampen out the vibrations that are there. For those that are shipping items that do require a specific temperature, this is a good insulation foam.

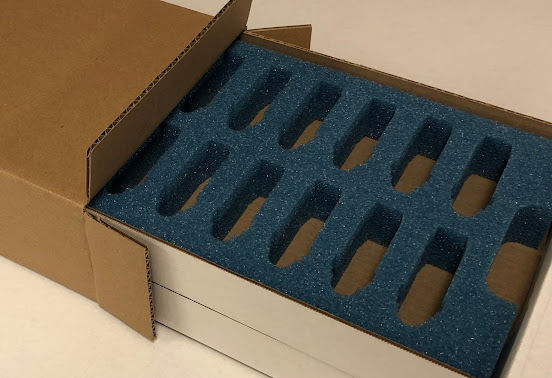

That, along with the chance that it can resist the liquids that are there, this protects all of the products from elements outside, and it’ll arrive at the destination just as how it left your warehouse as well. PE can also be made in different types of ways, depending on what’s necessary. That’s because foam is very customizable and is a great option for those who need flexible packaging protection and solutions.

It can be used as planks, crosslinked, laminated, rolled, and skivvied if you need it. You also can get this in a range of different colors and sizes to the best fit of needs. This is one option that offers a stronger and more durable protection because of the seal on top of this, and a closed cell type of construction that this offers.

This is actually the best packaging option that will help you if you want to make sure that something gets enough resistance to liquid, some buoyancy, and also strength too in this case. It can survive bumps, and it can go through impact after impact while continuing to stary in shape as well, which is why lots of people do like this kind of thing.

It can have a thick density too, offering the ultimate means to actually ship something that needs to be kept safe. This is definitely a good option if you want high-quality foam packaging that’ll stay tight and secure throughout the entirety of the journey at hand that you may go on.

Is it right for you? Well if you want something that’ll survive all sorts of jumps and jarring motions, this is the way to do it, and it offers a lot of great benefits to be had as a result too, and there is a lot of great of great benefits that you can use to totally get the benefits of this as well for you and for your business.

No comments:

Post a Comment